Aerodynamic engineering has seen a significant transformation in recent years, thanks to the advancements in deep learning tools. These tools have revolutionized the way planes, cars, and ships are designed, making them more fuel-efficient and structurally refined. A new computational model developed by researchers at KTH Royal Institute of Technology, in collaboration with experts from the U.S. and Spain, has taken the science of reproducing airflow to new heights. This model, published in Nature Communications, leverages neural network architecture to make accurate predictions while also saving time, cost, and energy.

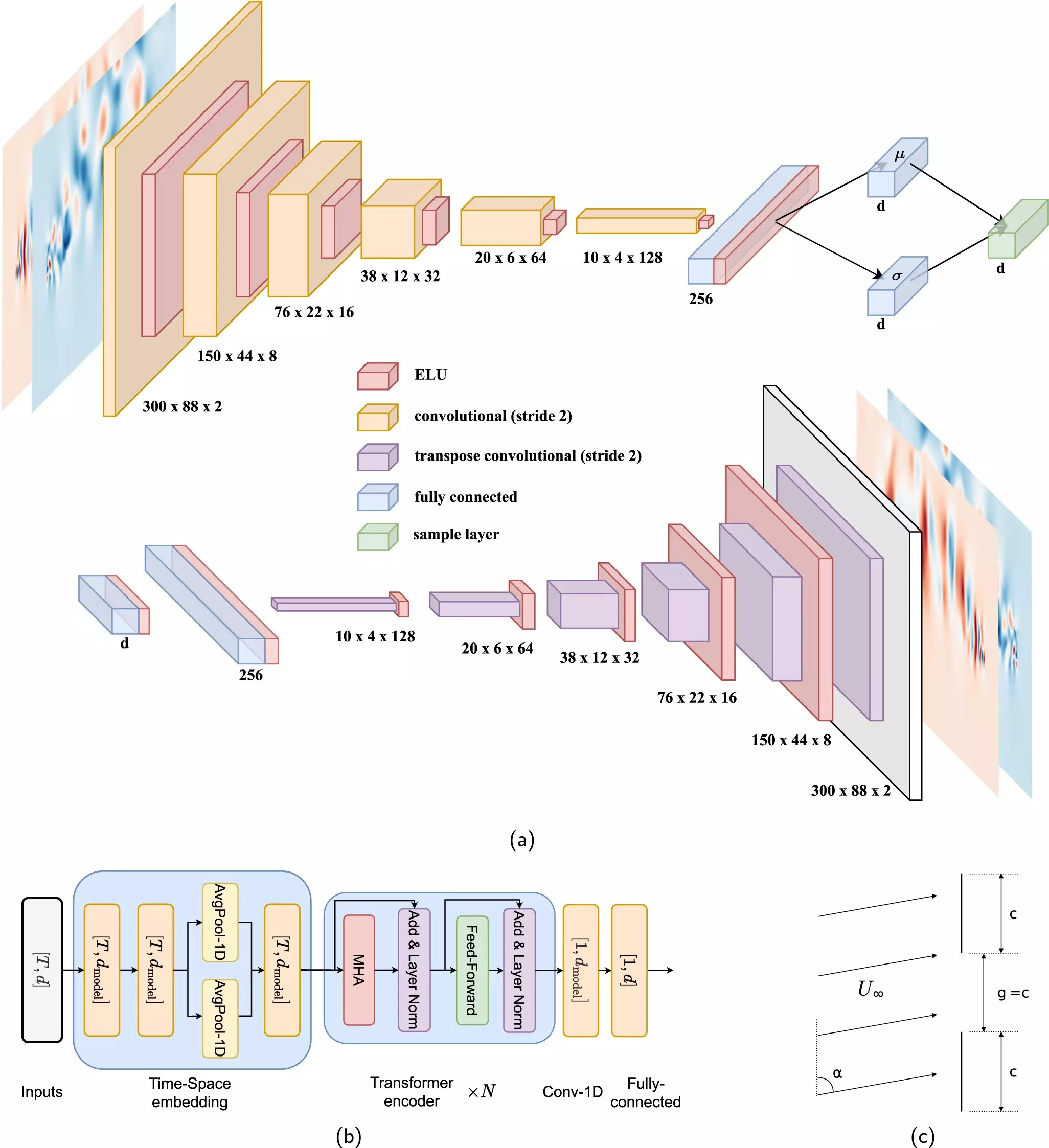

Traditional reduced order modeling in fluidics relies on linear computation, which produces predictions through basic arithmetic operations. However, the new model introduced by researchers at KTH Royal Institute of Technology goes a step further by incorporating neural networks. Unlike linear models, neural networks have the ability to learn and map intricate relationships between input and output data. This capability is particularly valuable when dealing with the complex task of predicting and modeling air friction near the surface of an airplane wing or a train engine. By utilizing neural networks, engineers can better understand how airflow changes over time, allowing for more effective control of the flow to reduce drag and improve aerodynamic design.

The new computational model developed by the researchers at KTH Royal Institute of Technology can capture most of the original physics in a flow prediction, achieving an accuracy of 90% or more with relatively low processing complexity. In comparison, traditional linear models such as proper-orthogonal decomposition (POD) and dynamic-mode decomposition (DMD) face challenges in reaching this level of accuracy due to the simplification of relationships into straight lines and planes. The complexity of real-world aerodynamics requires models that can account for various shapes and patterns in order to make precise predictions.

Aerodynamic drag is a significant contributor to global emissions, making it crucial to develop technologies that can reduce drag and improve overall efficiency. By implementing aerodynamic control technology based on the new computational model, reductions in drag of up to 20%, 30%, or even 50% can be achieved. This can have a significant environmental impact and play a vital role in determining the future trajectory of global warming scenarios.

The integration of deep learning tools and neural network architecture into aerodynamic engineering has paved the way for more accurate predictions, improved efficiency, and reduced environmental footprint. The new computational model developed by researchers at KTH Royal Institute of Technology represents a significant leap forward in the field of aerodynamics, offering a promising solution for the challenges faced in predicting and controlling airflow.

Leave a Reply