Additive manufacturing, also known as 3D printing, has revolutionized the manufacturing industry by allowing the creation of components with complex three-dimensional shapes and internal features that were previously unattainable. However, one of the biggest challenges in this process is identifying defects in the manufactured components. These defects can be difficult to detect due to the intricate nature of the components, making it crucial to develop innovative methods for defect detection.

Researchers at the University of Illinois Urbana-Champaign have introduced a groundbreaking method for detecting defects in additively manufactured components using deep machine learning. By utilizing computer simulations to generate synthetic defects with varying sizes, shapes, and locations, the deep learning model was trained to differentiate between defective and defect-free components. This approach proved to be highly effective, with the algorithm successfully identifying hundreds of defects in physical parts that were previously unseen by the model.

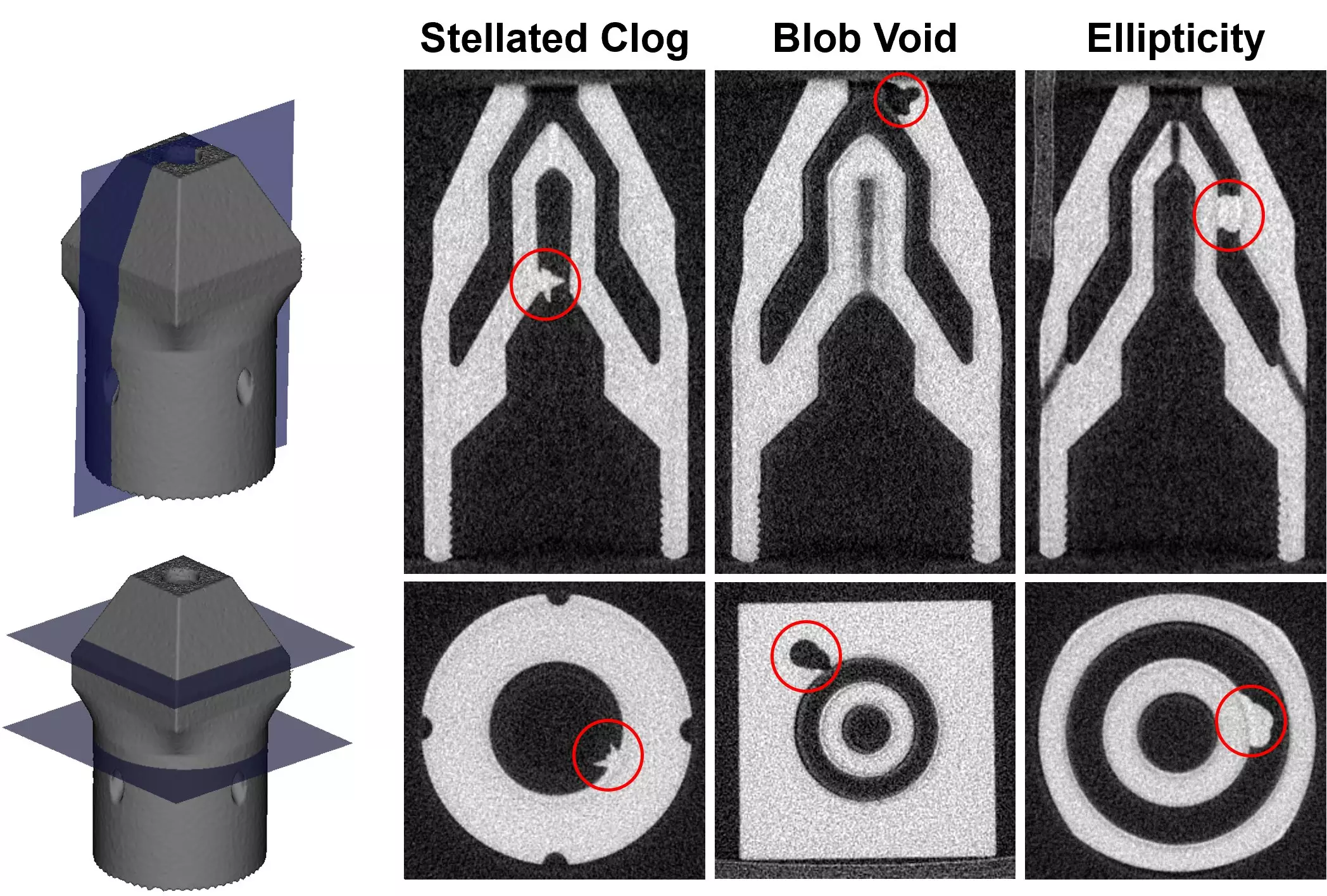

In their study, the researchers employed X-ray computed tomography to inspect the interior of 3D components, particularly those with hidden defects and internal features. This technology enables a comprehensive analysis of the components, allowing for the detection and classification of defects that are not visible to the naked eye. The combination of deep learning and X-ray computed tomography has proven to be a powerful tool in addressing the challenges of additive manufacturing.

The research, published in the Journal of Intelligent Manufacturing, highlights the impact of utilizing deep learning and advanced imaging techniques in defect detection. The authors, including experts from various universities, emphasize the importance of leveraging technology to overcome the hurdles faced in additive manufacturing. By integrating computer simulations, machine learning, and X-ray computed tomography, the researchers have demonstrated the potential to enhance the quality and reliability of additively manufactured components.

Overall, the development of new technologies and methodologies for defect detection in additive manufacturing is crucial for ensuring the production of high-quality components. The integration of deep learning and advanced imaging techniques represents a significant advancement in this field, offering a promising solution to the challenges associated with identifying defects in complex components. As the manufacturing industry continues to evolve, the incorporation of innovative technologies will play a key role in driving progress and improving the overall efficiency of manufacturing processes.

Leave a Reply