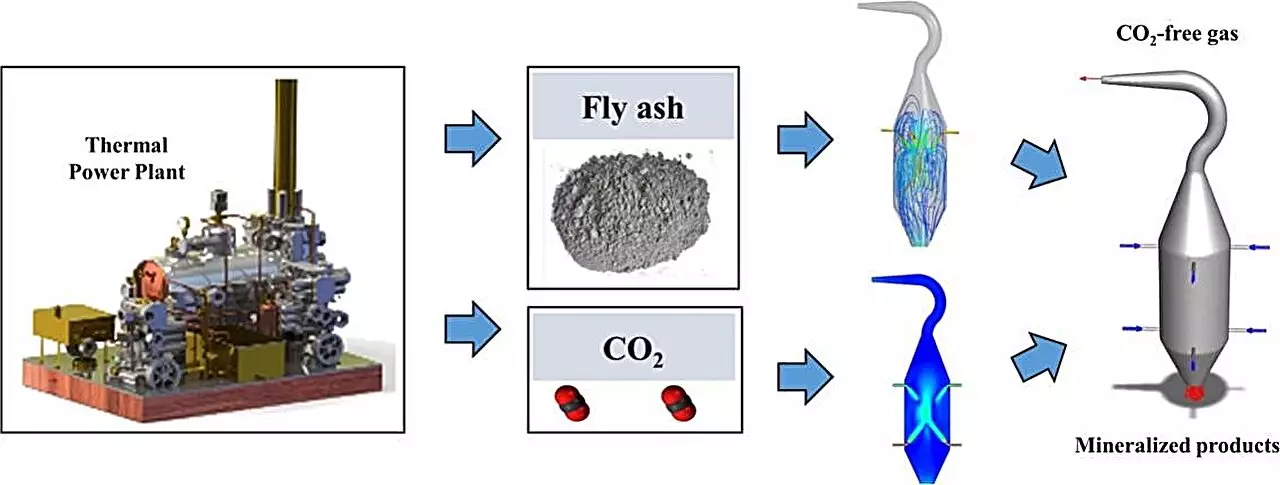

The recent advancements in sustainable waste management and CO2 sequestration research have introduced groundbreaking reactor designs that utilize fly ash particles to mineralize carbon dioxide. This innovative approach not only addresses the urgent issue of greenhouse gas emissions but also repurposes industrial by-products, offering a sustainable and long-lasting solution.

Existing carbon capture, utilization, and storage (CCUS) technologies have been struggling with efficiency and cost issues, making it crucial to explore new avenues for CO2 mineralization. Fly ash, a by-product of coal combustion, has emerged as a promising candidate for this purpose, effectively turning waste into a valuable resource while reducing emissions.

However, traditional reactor designs have faced challenges in achieving the desired level of synergy between gas-particle interactions and operational effectiveness. This highlights the need for a detailed investigation into novel reactor configurations and operational optimization to enhance performance.

Research Breakthrough

A recent study conducted by Shanghai Jiao Tong University and published in the Energy Storage and Saving journal on May 7, 2024, focused on developing efficient fly ash mineralization reactors through computational optimization. The research introduced two distinct reactor designs, each specifically tailored for CO2 mineralization using fly ash and leveraging computational fluid dynamics for optimization.

One of the designs, the impinging-type inlet design, was notable for its ability to enhance interfacial interactions, prolong particle residence times, and significantly increase mineralization rates. On the other hand, the quadrilateral rotary-style inlet design prioritized streamlined flow for thorough mixing and improved reaction efficiency.

By meticulously exploring operational parameters such as flue gas velocity, carrier gas velocity, and particle velocity, the study identified optimal ranges that promise to elevate reactor performance, ensuring efficient CO2 mineralization and phase separation post-reaction.

Impact and Implications

Dr. Liwei Wang, the principal investigator of the study, emphasized the significance of these findings in advancing carbon capture and utilization technologies. Through the refinement of reactor designs and operational parameters, the research achieved a substantial improvement in CO2 mineralization efficiency, offering a practical strategy for reducing industrial carbon emissions and promoting sustainable waste management.

The implications of this research extend beyond the laboratory, particularly for coal-fired power plants that produce significant amounts of fly ash. By redirecting this by-product towards CO2 mineralization, the study not only reduces carbon emissions but also alleviates the environmental burden associated with fly ash disposal.

In addition to its immediate benefits, the research holds promise for wider applications in waste management and CO2 sequestration, potentially reshaping the approaches to CCUS technologies. By presenting a holistic solution that combines waste repurposing and emission reduction, this research signals a new era in sustainable practices and environmental stewardship.

Leave a Reply