The field of water electrolysis technology has seen a significant breakthrough in South Korea with the development of a one-step electrode fabrication process by a research team led by Dr. Sung Mook Choi of the Korea Institute of Materials Science. This innovative process, detailed in the journal Applied Energy, has the potential to revolutionize the production of electrodes for anion exchange membrane water electrolysis systems.

The Breakthrough Process

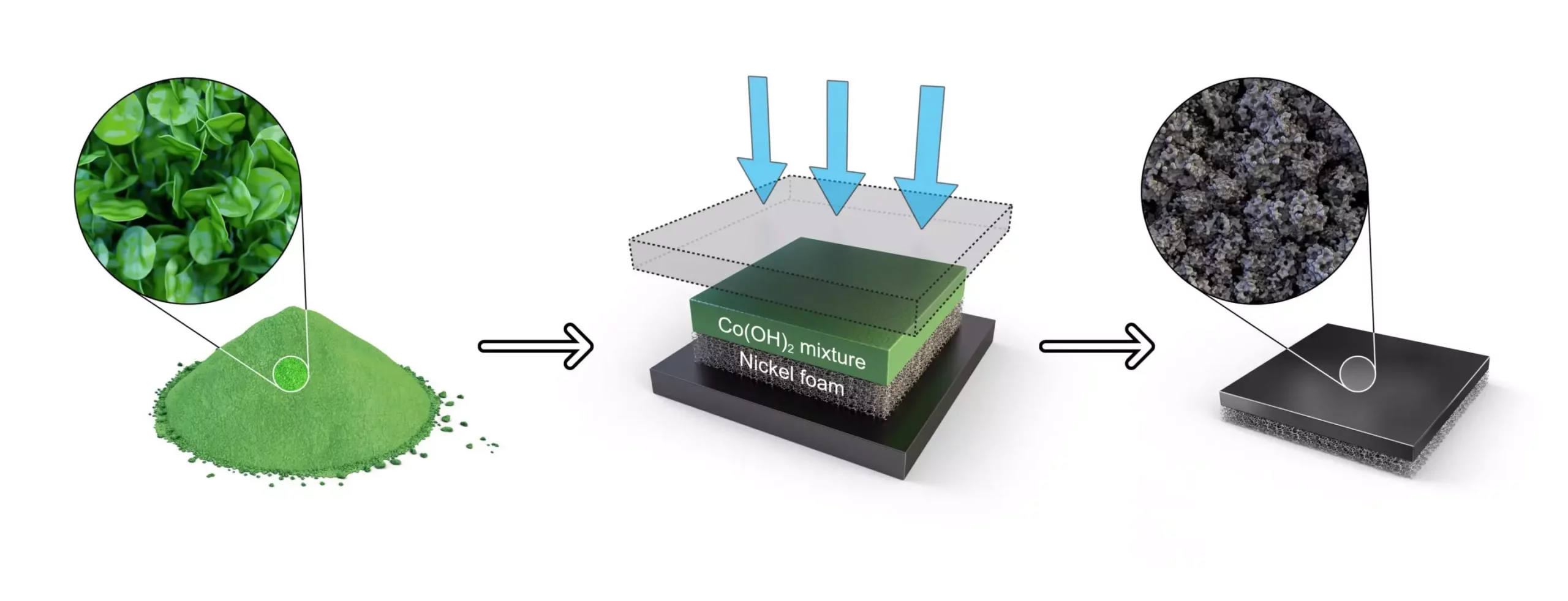

The one-step electrode fabrication process developed by Dr. Choi’s research team streamlines the production of electrodes by directly converting raw materials into electrodes on a mass-producible scale. This process eliminates the need for multiple complex steps involved in traditional electrode fabrication methods, such as hydroxide-oxide-crushing-dispersion-coating-drying, and replaces them with a single coating step. The result is a more efficient and simplified electrode fabrication process, reducing production time and costs by 60%.

One of the key achievements of this new process is the creation of a highly uniform catalyst layer through a hot-pressing technique that converts cobalt hydroxide into a cobalt oxide catalyst. By carefully controlling the slurry conditions, temperature, and pressure during the hot-pressing process, the research team was able to fabricate a catalyst layer composed of uniform oxide particles, each 10 nanometers in size. This level of precision and uniformity resulted in improved efficiency of hydrogen production and enhanced durability during continuous operation.

The developed electrode was successfully integrated into a membrane electrode assembly (MEA) for use in a commercial-scale water electrolysis cell, demonstrating stability and high performance. This technology has the potential to revolutionize green hydrogen production, with projections indicating a significant increase in capacity by 2030. Efforts are underway in Korea to develop a megawatt-level anion exchange membrane water electrolysis system by 2024, with aims to commercialize the technology by 2030.

The advancement in water electrolysis technology in South Korea signifies a move towards self-sufficiency and global competitiveness in the field. By securing the source technology for mass-produced electrode manufacturing, Korea aims to dominate overseas water electrolysis markets and establish itself as a leader in the industry. Dr. Sung Mook Choi emphasized the importance of this breakthrough in addressing key challenges related to the commercialization of anion exchange membrane water electrolysis.

The development of the one-step electrode fabrication process in South Korea marks a significant milestone in water electrolysis technology. This breakthrough not only streamlines the production process and enhances efficiency but also positions Korea as a key player in the global market for water electrolysis technology. With continued research and development in this field, the future looks promising for sustainable and efficient hydrogen production.

Leave a Reply