In the fast-paced world of modern technology, the significance of energy-efficient systems cannot be overstated. Amid discussions on sustainable practices, small electric motors play an unsung role in numerous applications, ranging from household appliances to automotive systems. While each motor may contribute a modest energy load individually, when combined, their cumulative impact on energy consumption becomes substantial. Recent advancements in motor design and control technology, spearheaded by researchers at Graz University of Technology, offer promising insights into maximizing this energy-saving potential.

Understanding the Role of Small Electric Motors

Electric motors are ubiquitous in everyday devices. From refrigerators turning cooling fans to car systems powering pumps, these motors perform essential functions behind the scenes. Despite their small size and individual energy consumption, collectively, they can lead to significant savings on energy bills and contribute to a more sustainable future. As energy costs continue to rise and the global demand for efficiency increases, innovations in motor technology are paramount.

The recent efforts by the team led by Annette Mütze at the Electric Drives and Power Electronic Systems Institute focus on brushless motors, particularly for applications such as pumps and fans. Traditional motor designs often yield inefficiencies that can be addressed through innovative engineering. Among the team’s breakthroughs is the remarkable reduction in “cogging torque,” a term that refers to the jerky motion experienced in motor rotation due to uneven engagement of magnetic components. By ingeniously skewing and slotting the claws of the motors, Mütze’s team achieved a 70% reduction in noise generation, yielding a smoother and quieter operation. Such advancements not only enhance user experience but also promote environmental considerations by reducing noise pollution.

Energy efficiency in electric motors is directly tied to the methods of current regulation employed. Traditional pulse width modulation (PWM) methods require frequent switching operations, which escalate energy consumption. The novel approach developed by Mütze’s team simplifies these current control methods by limiting switching events to a single activation per desired shape. This significant reduction in operational complexity leads to lower energy losses, especially notable at lower currents. Consequently, the motors exhibit a markedly elevated overall efficiency when compared to conventional PWM-controlled systems. The implications of this advancement extend beyond performance metrics to tangible cost reductions, as the need for capacitors on circuit boards is halved.

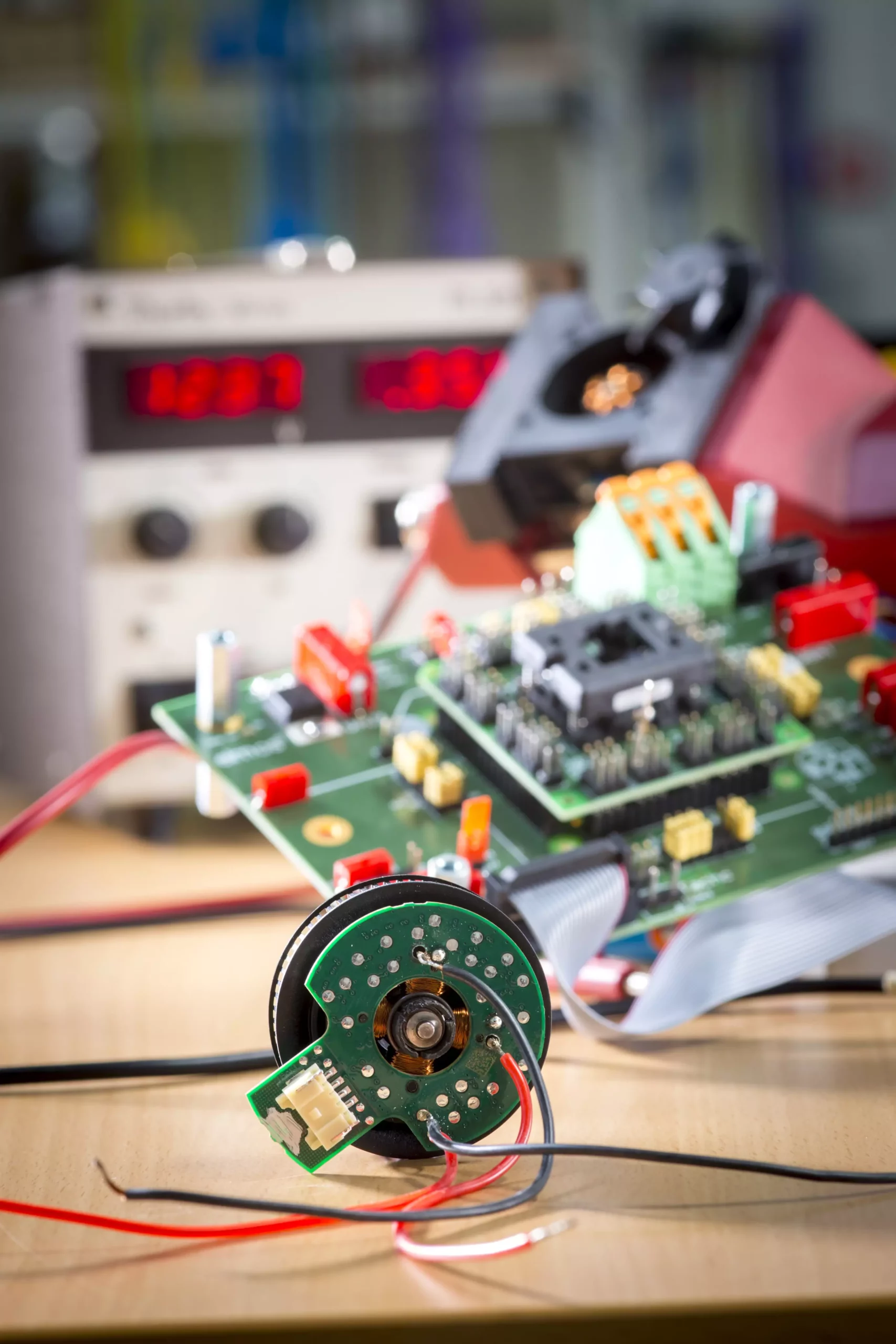

Further innovation in this research is characterized by the integration of PCB (Printed Circuit Board) motors utilizing ferrite cores. This modern manufacturing approach simplifies the production process, allowing for enhanced automation while simultaneously leveraging ferrite materials for magnetic field generation. These innovations bolster the motors’ overall effectiveness and lower production costs, paving the way for economical yet robust electric motor solutions. The use of 3D-printed ferrite cores to improve magnetic flux guidance illustrates a remarkable intersection of modern fabrication methods and traditional motor design.

The research undertaken by Mütze and her team signifies a crucial stride toward energy-efficient motor technology, with profound implications for countless applications. By reducing noise pollution, improving energy efficiency, and integrating cost-effective materials into motor design, these advancements offer a blueprint for future innovations in electric motor technology. As the global community continues to seek out sustainable solutions for energy consumption, this groundbreaking research exemplifies how even slight modifications in engineering principles can lead to significant enhancements in performance and efficiency. Ultimately, as these innovations are implemented, they hold the potential to rewrite the standards for electric motors and push us closer to achieving a greener technological landscape.

Leave a Reply