In the face of escalating environmental concerns and a growing dependence on high-tech solutions, the recent breakthrough from Kyoto University’s engineering team heralds a transformative approach to recycling rare-earth elements (REEs). Highlighted by the innovative selective extraction–evaporation–electrolysis (SEEE) process, this method not only showcases technological advancement but also aligns with sustainable practices—offering a beacon of hope in the recycling sector. As the demand for modern applications such as electric vehicles (EVs) and wind turbines continues to surge, the ability to recycle essential materials like neodymium (Nd) and dysprosium (Dy) becomes increasingly critical.

Rare-earth elements are not merely a footnote in the world of engineering; they are pivotal in powering some of the leading technologies shaping our planet’s future. Neodymium and dysprosium, in particular, serve as vital components in high-performance magnets necessary for green technologies. As global initiatives strive for carbon neutrality, the quest for an efficient and sustainable method to recycle these elements is paramount. The SEEE process from Kyoto University seeks to fill this gap, potentially reducing reliance on environmentally taxing mining processes.

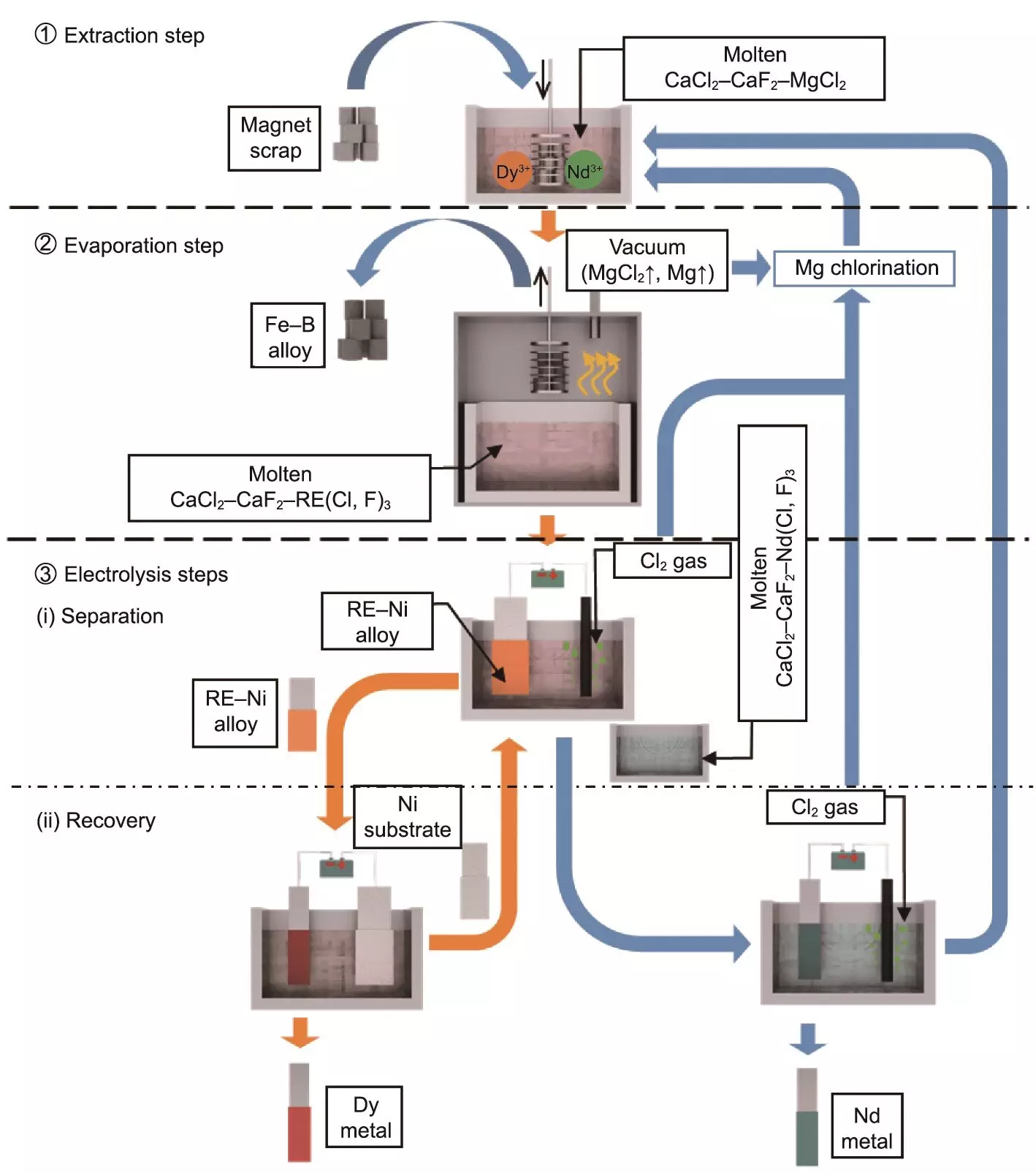

The SEEE approach stands out with its environmentally friendly and streamlined methodology compared to conventional recycling practices that are often cumbersome. This newly developed process encompasses three primary stages: selective extraction, selective evaporation, and selective electrolysis.

In the initial stage, the process utilizes a molten salt mixture composed of calcium chloride (CaCl2) and magnesium chloride (MgCl2) to extract the desired REEs from scraps of expired magnets. Adding calcium fluoride (CaF2) plays a crucial role in minimizing evaporation losses and enhancing extraction efficiency. The second stage focuses on the removal of any remaining byproducts, allowing for the concentration of the extracted REEs. The final stage employs electrolysis to separate the REEs based on their distinct electrochemical properties, thus enabling the recovery of high-purity metals like neodymium and dysprosium.

The preliminary results from this innovative study are notably encouraging. The SEEE process has reportedly achieved an impressive recovery rate of 96% for neodymium and 91% for dysprosium, with both metals attaining purities greater than 90%. Such efficiency provides a robust alternative to the inefficiencies associated with existing recycling techniques. Moreover, as the landscape of energy generation shifts more towards renewables, the SEEE process proves to be a valuable asset, ensuring a sustainable supply chain for these critical materials while minimizing the ecological footprint of new mining operations.

The potential applications of the SEEE process extend beyond just neodymium magnets. Researchers speculate that its principles could be adapted for more extensive uses, such as in the reprocessing of nuclear fuels—a development that could have substantial implications for multiple sectors.

While the SEEE method marks a significant advancement, the journey towards full-scale industrial adoption remains ongoing. The researchers acknowledge that further technical evaluation is integral to refining the method and ensuring its integration into industrial practices. Nevertheless, these findings provide a pivotal step towards more sustainable recycling methods, showcasing the potential of advanced research in navigating the complexities of environmental challenges today.

As nations globally pivot towards greener technologies to combat climate change, innovative solutions like the SEEE process become essential in addressing the scalability and environmental challenges of rare-earth element recycling. With a renewed focus on sustainable practices, this research emphasizes the need for continued exploration and development in the field of material recycling, ensuring alignment with broader carbon-neutral objectives. The SEEE process does not merely promise to revolutionize the recycling sector; it embodies a crucial step in the journey towards a sustainable future.

Leave a Reply