The landscape of structural engineering is continually evolving, and a recent study published in Engineering has ushered in a new era for the analysis of ultra-high-performance concrete (UHPC) confined by fiber-reinforced polymers (FRP). Researchers S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie have systematically explored the previously underappreciated aspects of UHPC behavior under confinement, challenging established paradigms. This groundbreaking work fills a significant gap in our understanding of UHPC, particularly how the material performs under specific stress conditions that prior models could not accurately depict.

In recent years, UHPC has gained traction within the construction sector, largely due to its remarkable strength and long-lasting durability. Engineers are increasingly recognizing its potential to enhance structural integrity. However, the challenge lies in understanding its behavior when subjected to external confining forces, such as those introduced by FRP. Traditional stress-strain models have proven effective for normal-strength concrete (NSC) under similar conditions, but applying these models to UHPC has consistently resulted in suboptimal predictions, highlighting the necessity for a new analytical framework that accurately reflects the complexities of UHPC under confining stress.

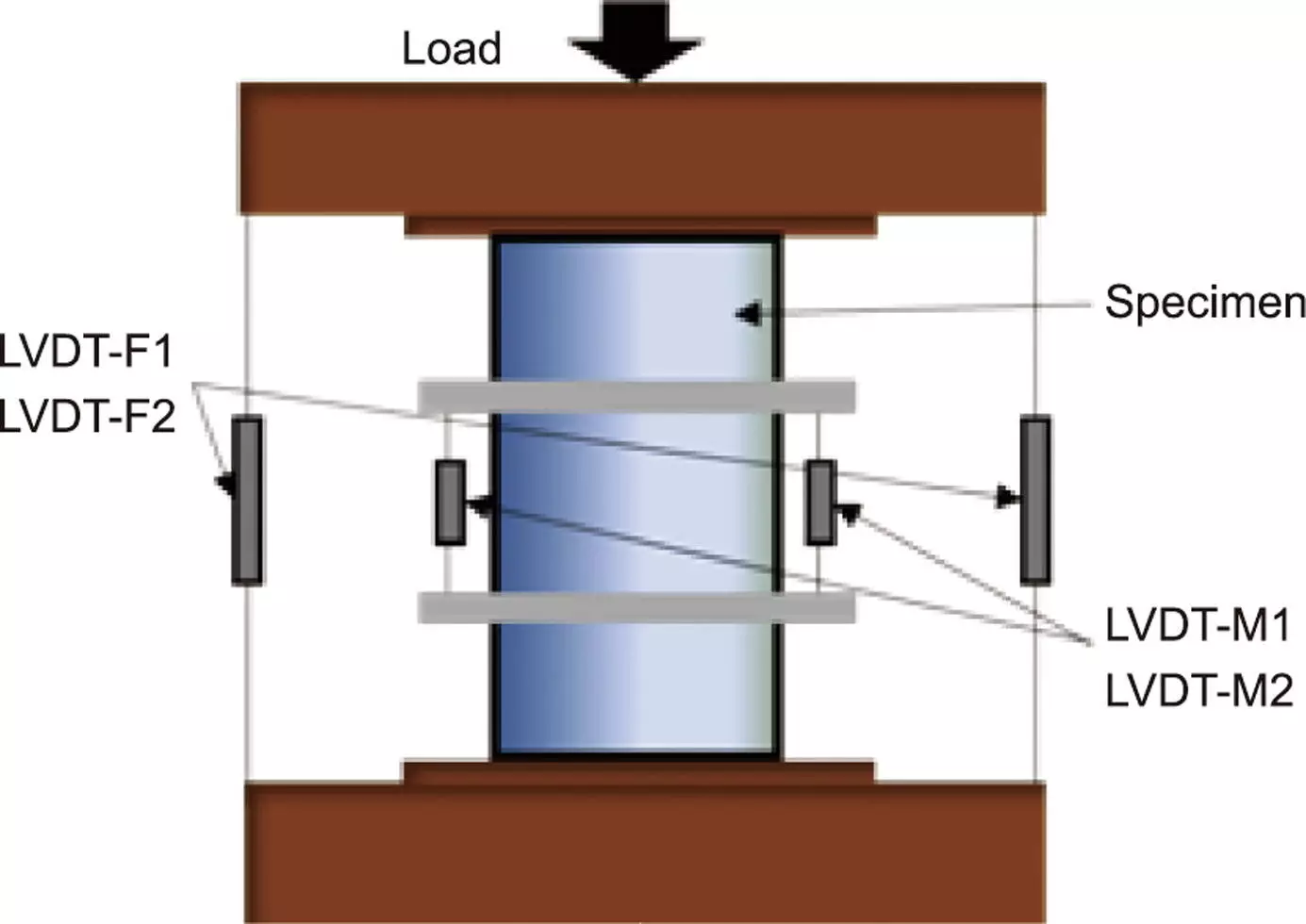

Conducted by an accomplished team from Huazhong University of Science and Technology and Southern University of Science and Technology, the study delves into the failure mechanisms of UHPC subjected to concentric compression. The researchers executed a series of concrete experiments to observe the intricate interplay between UHPC and FRP confinement. A pivotal finding was the realization that the prevalent assumption of stress-path-independency—a principle that has served the engineering community well in the context of NSC—fails to represent UHPC’s unique behavior.

The investigative work revealed the unexpected phenomenon of non-uniform lateral expansion due to the formation of significant diagonal cracks, which consequently reduced the effective confining pressure applied by the FRP. Recognizing this limitation necessitated a reconsideration of existing models, which had, until this point, overlooked the nuanced interactions between materials.

To address the limitations of prior models, the team pioneered the development of a new analytical model that integrates the principles of stress-path dependency. This innovative framework adjusts the assumptions regarding confining pressure, employing a revised equation designed to encapsulate the identified confining pressure gap. By doing so, they advanced a model capable of depicting UHPC’s distinctive interactions under confinement, thus providing engineers with a more valuable tool for design considerations.

The validation of this model was meticulously undertaken using a comprehensive experimental database, ensuring robustness and reliability in the findings. The results underscored the model’s superior capacity to predict the stress-strain responses of FRP-confined UHPC accurately, marking a significant leap forward in concrete research.

The ramifications of this research extend far beyond theoretical specifications; it stands to transform real-world applications in the construction sector. By integrating the new model into their design practices, engineers will enhance the safety and longevity of structures built with UHPC. The capacity to predict concrete behavior under unique stress conditions heralds a new chapter in efficiently designing various structural applications, potentially reducing maintenance costs and improving safety standards.

Furthermore, this advancement opens avenues for future academic inquiries. As researchers delve deeper into the complexities of UHPC and its interactions with confining materials, the insights gained could foster novel concrete applications, pushing the boundaries of engineering potential.

The recent strides made in understanding the mechanics of UHPC confined by FRP represent a meaningful leap in the structural engineering discipline. The introduction of an analysis-oriented model that factors in stress-path dependency not only enhances design accuracy but also carves new paths for exploration within concrete technology. As the industry embraces these insights, we can anticipate a renaissance in high-performance concrete applications that will fortify the resilience of our infrastructural systems.

Leave a Reply