The construction industry is currently facing a myriad of challenges that could potentially hinder its sustainability in the future. One of the major issues is the depletion of natural sand, which is a crucial resource for construction activities. It is predicted that by the year 2050, the world might run out of natural sand, leading to a scarcity that could significantly impact the construction sector. Additionally, the sector is also grappling with the escalating carbon dioxide emissions, particularly from the manufacturing of cement and fired clay bricks. These emissions contribute to the overall carbon footprint of the construction industry, making it a significant contributor to global greenhouse gas emissions. Moreover, the generation of construction and demolition (C&D) waste is on the rise, with approximately 150 million tons being produced annually in India alone. The recycling rate for this waste is abysmally low, standing at only around 1%. These challenges highlight the urgent need for sustainable solutions to ensure the longevity and environmental friendliness of the construction sector.

Researchers at the Center for Sustainable Technologies (CST) at the Indian Institute of Science (IISc) are at the forefront of exploring innovative solutions to address the challenges facing the construction sector. One of the key areas of focus for the researchers is the storage of carbon dioxide from industrial flue gas in excavated soil and C&D waste. These materials can then be utilized to partially replace natural sand in construction activities, thereby reducing the environmental impact of construction materials. This groundbreaking research not only aims to mitigate the negative effects of resource depletion and carbon emissions but also seeks to enhance the properties of construction materials for improved performance. According to Souradeep Gupta, Assistant Professor at CST, the utilization and sequestration of carbon dioxide have the potential to revolutionize the manufacturing of low-carbon prefabricated building products, aligning with the nation’s decarbonization goals. Gupta’s team has conducted studies demonstrating that replacing natural sand with carbon dioxide-treated C&D waste in mortar, coupled with curing in a controlled, CO2-rich environment, can significantly accelerate the development of the material’s engineering properties. This method has been shown to enhance the compressive strength of the material by 20-22%, showcasing the potential for carbon sequestration to improve construction materials.

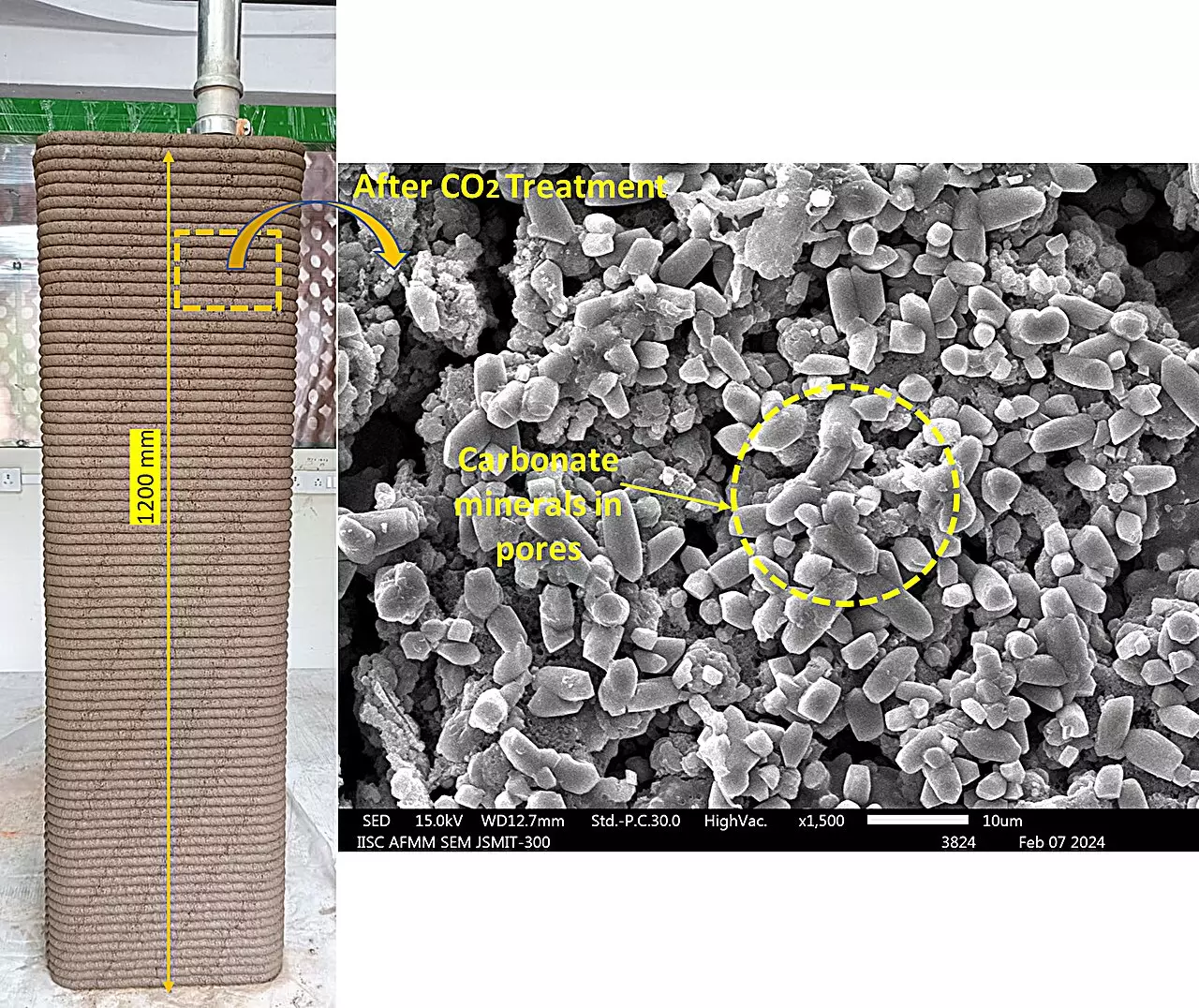

Further research by Gupta’s team has delved into the effects of injecting carbon dioxide gas into clayey soil typically excavated from construction sites. The results revealed improved stabilization of clay through the interaction with cement and lime, leading to enhanced engineering performance of the material. Additionally, the team explored the sequestration of carbon dioxide in excavated soil to develop cement-lime-soil materials, which can partially replace fine aggregates in mortar. The formation of calcium carbonates due to carbon sequestration resulted in the reduction of capillary pores, densification of interfacial zones, and an overall improvement in compressive strength. This innovative approach not only enhances the strength of construction materials but also reduces curing time, making them more efficient for use in construction projects. Moreover, the team has developed 3D-printable materials using excavated soil stabilized with a combination of binders, including Portland cement, blast furnace slag, and fly ash. These materials have shown superior extrusion and buildability compared to conventional cement-sand mortars, leading to a reduction in cement and natural sand consumption by 30% and 50% respectively.

Future Directions and Collaborations

As the research progresses, Gupta’s team is looking to expand their investigations to include the effects of industrial and simulated flue gas on the properties of newly formulated construction materials. By understanding how various gases impact the carbon-capturing potential and engineering properties of these materials, the team aims to further optimize their sustainability and performance. They are also in discussions with major construction companies to implement these innovative solutions in their manufacturing processes, paving the way for a more sustainable construction industry. Additionally, Gupta is actively involved in national efforts to revise standards for natural and recycled aggregates in cement-based construction materials, with a focus on mitigating the climate change impacts of construction activities. The collaborative approach taken by researchers and industry stakeholders heralds a new era of sustainable construction practices that prioritize environmental stewardship and long-term viability.

Leave a Reply