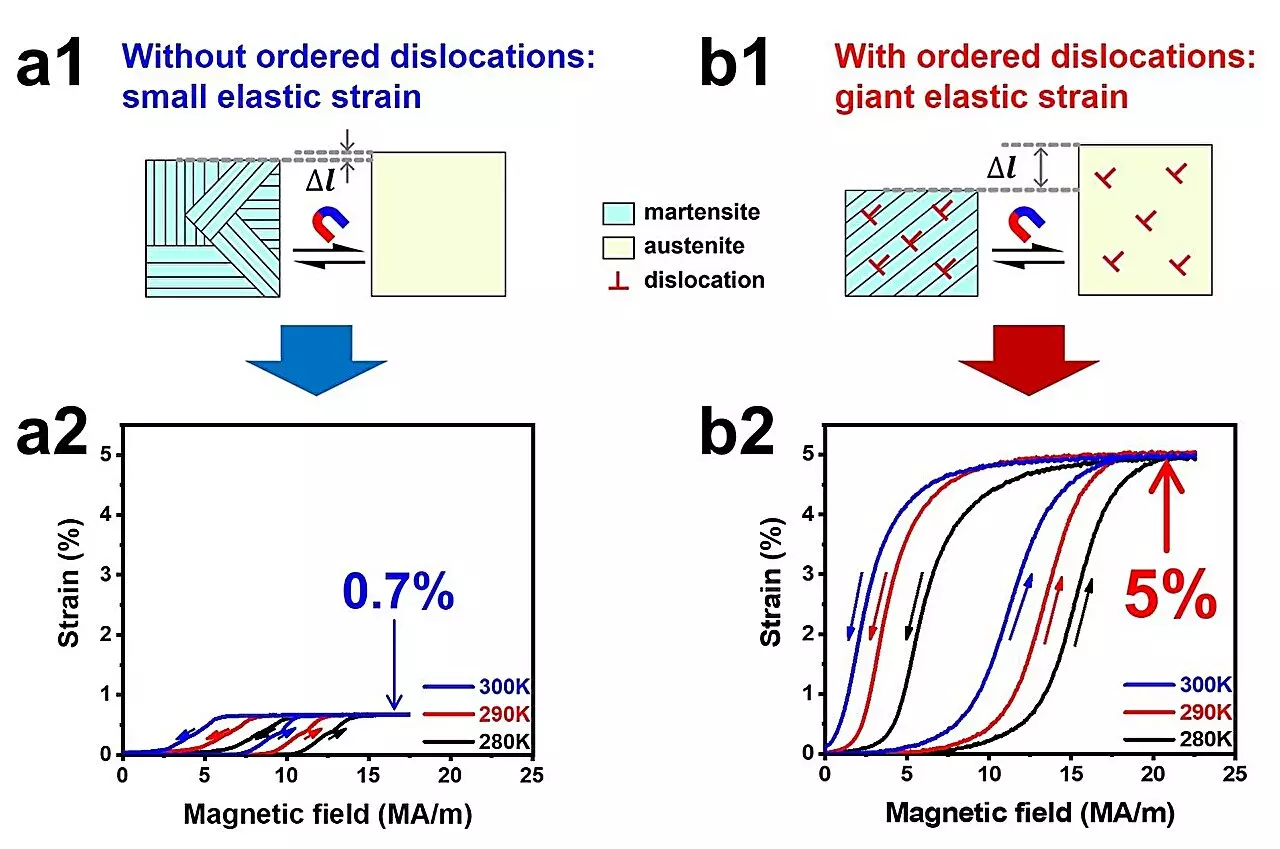

In a recent study published in Advanced Science, a groundbreaking achievement was made in the field of magneto-superelasticity. Researchers were able to develop a Ni34Co8Cu8Mn36Ga14 single crystal with a remarkable 5% magneto-superelasticity. This was accomplished through the introduction of ordered dislocations to form preferentially oriented martensitic variants during the magnetically induced reverse martensitic transformation.

Elasticity in materials is a crucial characteristic, allowing them to return to their original shape after deformation. While most metals typically have a strain limit of 0.2%, shape memory and high entropy alloys can exhibit superelasticity with strains of several percent. Magneto-superelasticity, induced by a magnetic field, is particularly important for contactless material operation and the development of new large stroke actuators and energy transducers.

The researchers collaborated with the High Magnetic Field Laboratory at the Hefei Institutes of Physical Science of the Chinese Academy of Sciences to conduct stress-constrained transition cycling (SCTC) training on the Ni34Co8Cu8Mn36Ga14 single crystal. This training involved applying compressive stress to introduce ordered dislocations with a specific orientation. These dislocations influenced the formation of specific martensitic variants during the reversible transformation induced by a magnetic field.

Phase field simulations confirmed that the internal stress generated by the organized dislocations played a crucial role in shaping the preferred martensitic variants. By combining reversible martensitic transformation with the preferential orientation of martensitic variants, the single crystal was able to achieve an impressive 5% magneto-superelasticity. Additionally, a device utilizing a pulsed magnetic field was designed with this single crystal, showcasing a large stroke at room temperature and a rapid response to pulses.

This groundbreaking research in magneto-superelasticity demonstrates the potential of defect engineering in creating high-performance functional materials. The findings not only advance our understanding of material behavior but also open up exciting possibilities for the development of innovative applications in various fields. Prof. Wang highlighted the importance of this work as a strategy to access high-performance functional materials through defect engineering, paving the way for further advancements in the field.

Leave a Reply