The University of Bristol researchers have made a groundbreaking discovery in the field of sensing technology that could potentially revolutionize the manufacturing sector in the United Kingdom. By developing a formula that can determine the design boundaries for the geometry and material microstructure of components, they have paved the way for a commercially viable sensing technology that can assess the quality of these components.

One of the key breakthroughs in this study is the utilization of ultrasonic array sensors, which are similar to those used in medical imaging. However, these new laser-based versions do not require direct contact with the material being assessed. This novel approach opens up possibilities for assessing safety critical components in industries like aerospace with greater efficiency and accuracy.

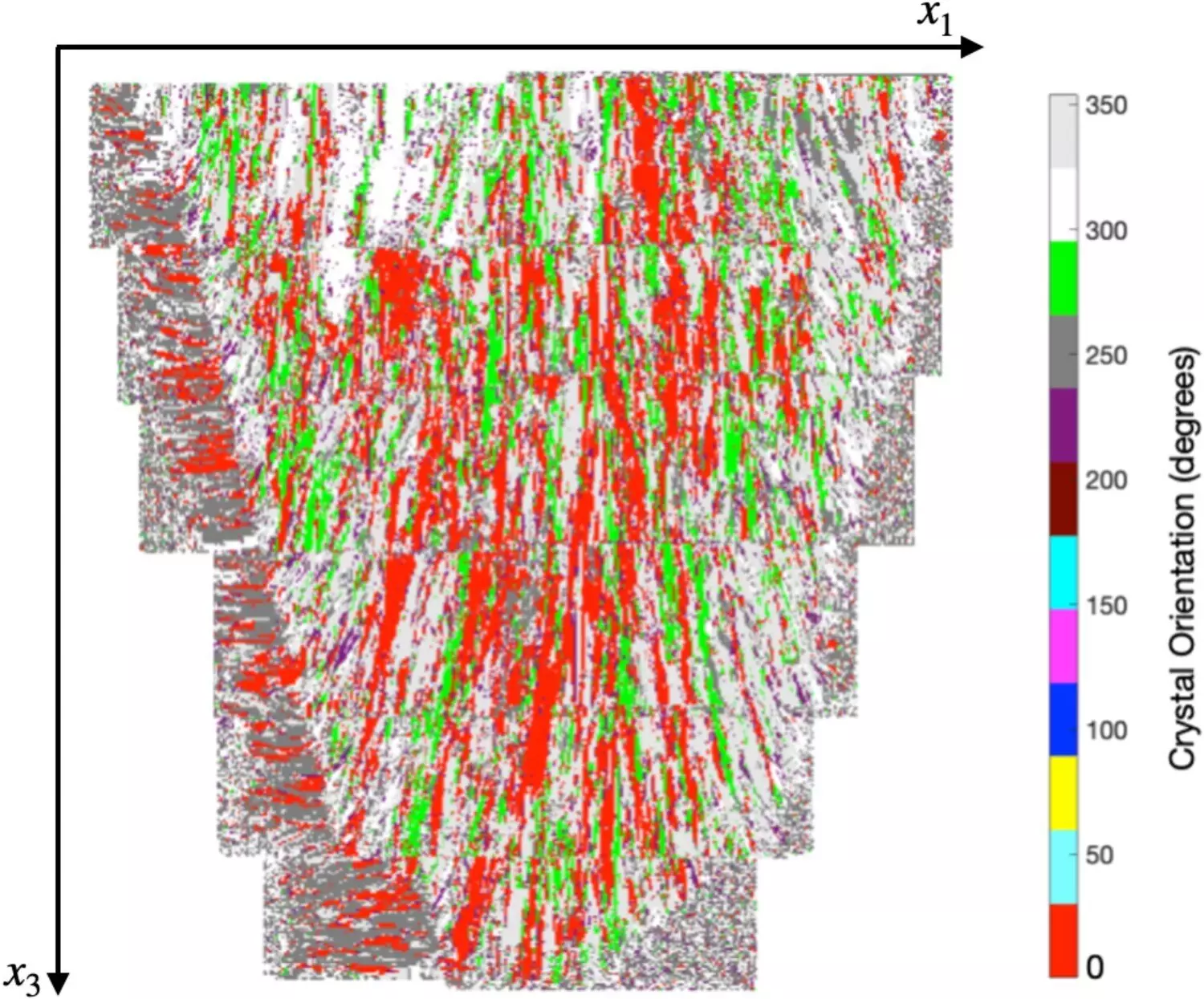

The researchers have constructed a comprehensive mathematical model that takes into account the physics of ultrasonic waves traveling through layered metallic materials. This model considers the variability present in each additively manufactured component and utilizes design parameters specific to ultrasonic lasers and material characteristics. The resulting output provides valuable information to assess the mechanical integrity of the component.

Implementing this sensing technology in additive manufacturing processes could lead to significant commercial advantages for the U.K. manufacturing industry. By ensuring that 3D printed metallic components meet safety and quality standards, companies can benefit from quicker production processes, new design opportunities, and a competitive edge in the marketplace.

The research team plans to collaborate with industry partners to deploy these laser-based ultrasonic arrays in controlled additive manufacturing environments. By maximizing the information content gathered by the sensors and developing customized imaging algorithms, they aim to generate detailed tomographic images of component interiors. These images will undergo destructive testing to validate their quality assessment capabilities.

The breakthrough in sensing technology developed by the University of Bristol researchers has the potential to transform the way safety critical components are manufactured and assessed in the U.K. This advancement could open up new opportunities for 3D printing in industries such as aerospace, providing a significant commercial advantage and economic benefit. By addressing the current lack of means to assess mechanical integrity, this technology could unlock a wealth of possibilities for the manufacturing sector.

Leave a Reply