In a groundbreaking study conducted by researchers from the University of Illinois Urbana-Champaign, diffusion in multicomponent alloys has been redefined as a sum of individual contributions known as “kinosons.” By utilizing machine learning to analyze the statistical distribution of these individual contributions, the team was able to develop a model for the alloy and determine its diffusivity in a significantly more efficient manner than traditional trajectory calculations.

The Significance of Diffusion in Solids

Diffusion in solids is a fundamental process through which atoms move within a material. Various industrial processes, such as steel production, ion movement in batteries, and semiconductor device doping, heavily rely on the controlled diffusion of atoms. The ability to understand and predict diffusion is crucial for enhancing material properties and optimizing manufacturing processes.

Diffusion in Multicomponent Alloys

The research focused on modeling diffusion in multicomponent alloys, which are composed of five different elements – manganese, cobalt, chromium, iron, and nickel in equal proportions. Multicomponent alloys are known for their unique properties, including excellent mechanical behavior and high-temperature stability. Therefore, it is essential to comprehend how atoms diffuse within these complex materials to leverage their full potential.

One of the major challenges in simulating diffusion is the requirement for long timescales to observe meaningful atom movement. Traditional simulations often demand extended periods to capture the full diffusion picture accurately. This limitation restricts the feasibility of using more accurate methods to calculate transition rates, as extensive simulation steps are needed to obtain reliable diffusion values.

The Concept of Kinosons

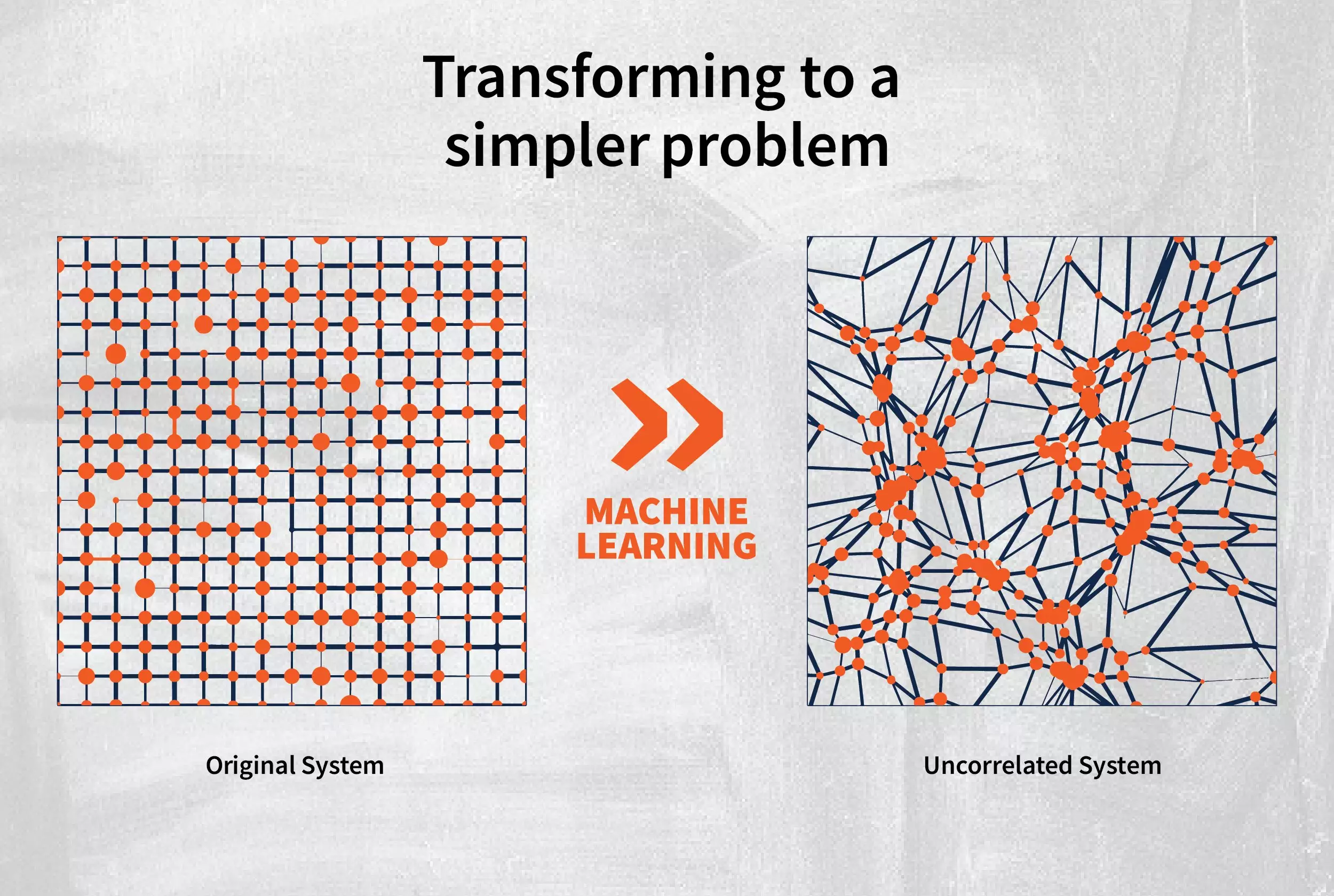

The concept of kinosons introduces a novel approach to understanding diffusion by considering each individual atom jump as a contributing factor. By breaking down diffusion into smaller, uncorrelated jumps, the calculation becomes more straightforward and efficient. Kinosons represent these incremental movements, allowing researchers to extract their distribution and probability, ultimately determining the diffusivity of the alloy.

The Role of Machine Learning

Machine learning plays a pivotal role in transforming the diffusion problem by eliminating correlated jumps and simplifying the calculation process. By leveraging machine learning algorithms, researchers can analyze the behavior of atoms within the alloy more efficiently and accurately. This innovative approach not only accelerates the simulation process but also provides insights into how different elements diffuse within the solid.

The utilization of kinosons and machine learning in modeling diffusion presents a paradigm shift in the field. This method offers a faster and more effective way to calculate diffusivity in multicomponent alloys, revolutionizing the traditional approach to diffusion studies. With the potential to accelerate simulations by a hundredfold, this innovative technique is poised to reshape the future of diffusion research and become the standard methodology in the coming years.

The research conducted by the University of Illinois Urbana-Champaign represents a significant advancement in the study of diffusion in multicomponent alloys. By redefining diffusion as a sum of individual contributions and incorporating machine learning techniques, researchers have unlocked a more efficient and accurate method for calculating diffusivity. This innovative approach not only enhances our understanding of diffusion processes but also paves the way for transformative developments in material science and engineering.

Leave a Reply