Granular systems, such as pharmaceuticals, cereal, and landslides, play a significant role in our everyday lives. From the sand in far-off planets to the concrete beneath our feet, granular materials surround us. However, these seemingly mundane materials hold secrets that could revolutionize our understanding of mixing. A group of researchers at the University of Rochester, led by Rachel Glade, an assistant professor of Earth and environmental sciences and mechanical engineering, have delved into the intricate world of granular systems. In their recent study published in the Proceedings of the National Academy of Sciences, Glade and her team have uncovered the unexpected influence of grain shape on the behavior of granular materials.

One peculiar phenomenon observed in granular materials is known as the “Brazil Nut Effect.” This phenomenon describes the tendency for larger grains to rise to the top of a mixture, leading to size-based segregation rather than uniform mixing. The Brazil Nut Effect poses challenges in various industries, such as food and medicine, as it hinders the desired homogeneity of mixtures. Moreover, this phenomenon has significant implications in natural processes like erosion, debris flows, and landslides. Despite the prevalence of the Brazil Nut Effect, the underlying mechanisms remain elusive. Previous studies primarily focused on the size of grains, assuming they are spherical, which is rarely the case in reality.

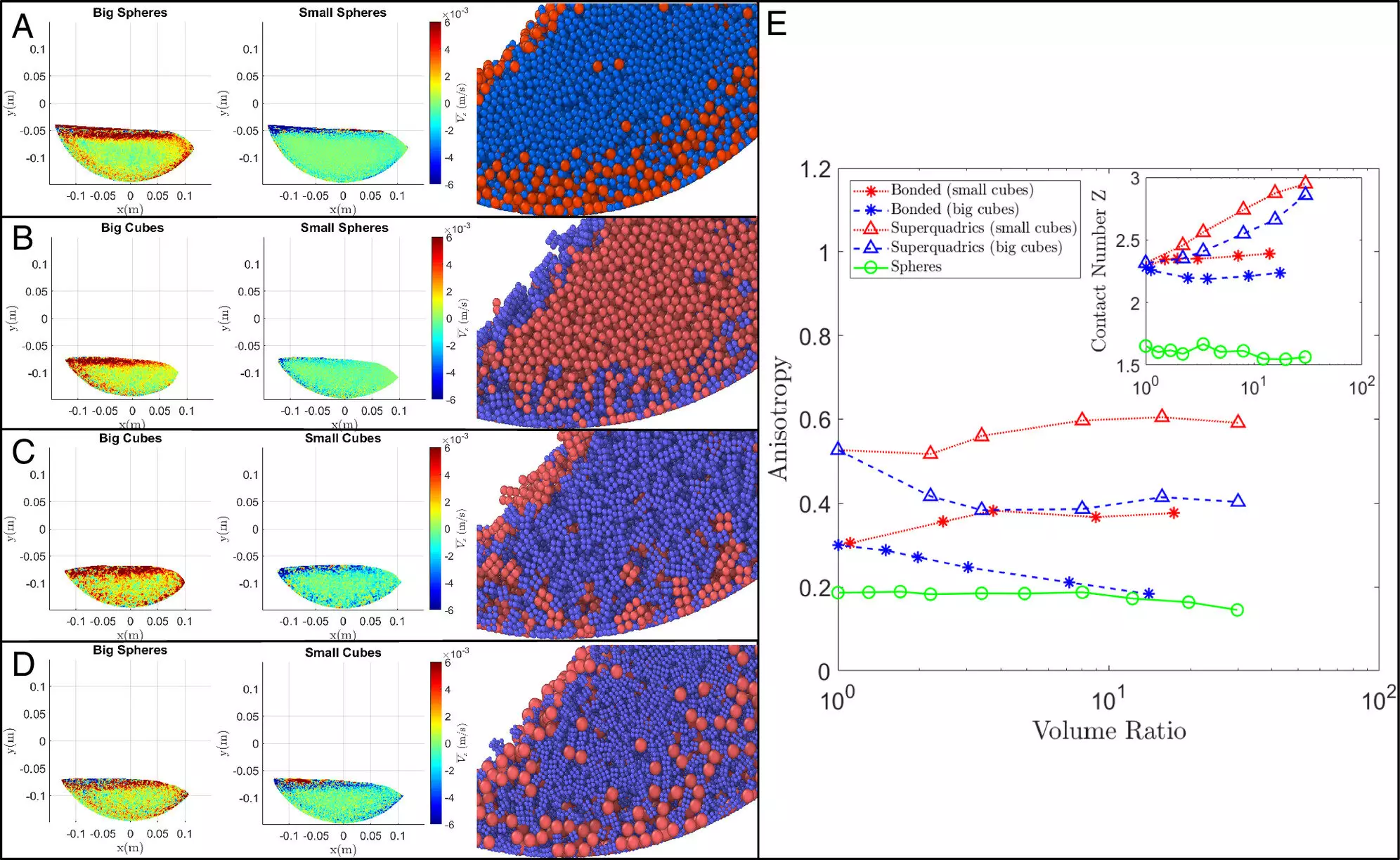

To shed light on the role of grain shape in segregation, Glade and her team conducted advanced computer simulations. They compared mixtures of spherical grains with mixtures containing both spheres and cubes, analyzing dry and wet conditions separately. The results of their research unveiled fascinating patterns in the behavior of granular systems.

In the dry-system mixtures, the researchers observed that an increased ratio between large-volume spheres and small-volume spheres led to a higher degree of segregation. This means that more significant spheres rose to the top of the mixture. Similarly, when mixtures included larger cubes alongside spheres of the same size, the segregation tendencies remained similar to those in the spheres-only case. Again, the larger spheres tended to rise to the top. However, when the mixtures included smaller cubes and spheres of the same size, the segregation decreased. Although most of the larger spheres still rose to the top, it occurred to a lesser extent compared to the spheres-only mixture.

Interestingly, the behavior in fluid systems showed a reverse trend. In mixtures of spheres of the same size with smaller cubes, the smaller cubes moved to the top. This contrasting behavior further emphasizes the role of grain shape in segregation. Glade explains, “Grain shape changes segregation both quantitatively – in the dry drum case where cubes reduce segregation – and qualitatively – in the wet river case where cubes alter segregation patterns.”

While these findings shed light on the interplay between grain shape and segregation, they also raise new questions. Glade and her team plan to investigate the underlying factors contributing to these changes in segregation. They suspect that various forces acting on the particles play a crucial role – these forces may cause particles to stick together and resist movement differently. Understanding these complex dynamics will be instrumental in further unraveling the mysteries of granular systems.

The research conducted by Glade and her team highlights the significance of interdisciplinary studies. By drawing inspiration from physics, engineering, and Earth science, the researchers have shown how grain shape impacts a wide range of domains. The implications of this research extend beyond granular materials; they extend to processes that affect our daily lives, from the manufacturing of pharmaceuticals to the stability of natural landscapes. Recognizing the importance of grain shape opens new avenues for innovation and problem-solving.

The study conducted by the University of Rochester researchers uncovers the unexpected role that grain shape plays in the behavior of granular systems. The findings challenge previous assumptions about the influence of grain size alone and emphasize the need to consider grain shape in understanding mixing and segregation. This groundbreaking research opens up new opportunities for industries and researchers alike to optimize mixing processes and better understand the behavior of granular systems in various fields.

Leave a Reply